Please click to download a (prettier) .PDF version of this maple syrup evaporator efficiency experiment,

| We have a new 3'x12' wood-fired evaporator with a steam hood, pre-heater, insulated firebox door, and blower. We noticed, however, that we weren't getting the efficiency out of it that might be expected, and so set out to first get a baseline of our boil rate with what we'd been doing thus far, and then to try changing our methodology in a controlled way so that we could determine what we should be doing differently. | |||||

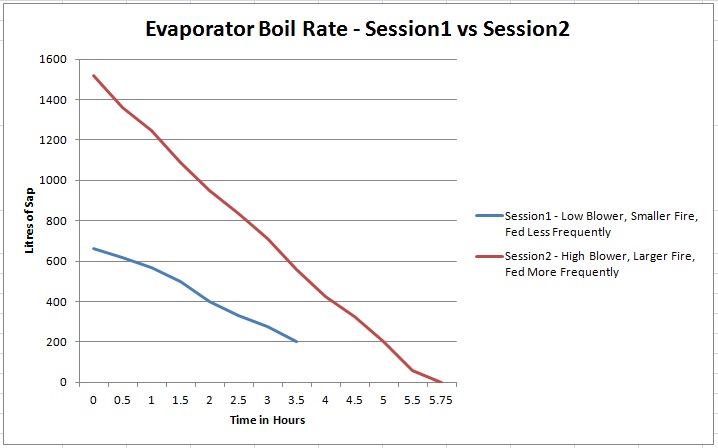

| We did two boils over two days using fresh sap and recorded our tank levels every 30 minutes once the evaporator and pre-heater had gotten up to operating temperature and we had a good, rolling, boil. The data from those two Sessions are recorded below along with notes on what variables had been changed and how much of a difference they made, and the conclusions that we've drawn from this experiment. | |||||

| There is further investigation and tweaking that we'll want to do, but this has been a good start - we've already doubled our evaporator's efficiency. | |||||

| Session 1: | Mixed use of seasoned Maple, wet Ash, seasoned Poplar | ||||

| Blower set to about 50% speed | |||||

| Fire fed roughly every 10 to 15 minutes with the fire concentrated at the front of the firebox | |||||

| Time (h) | Litres | L/hr rate taken every 30 mins | L/hr rate taken hourly | Session Average L/hr rate | |

| 0 | 662 | ||||

| 0.5 | 620 | 84 | |||

| 1 | 570 | 100 | 92 | ||

| 1.5 | 500 | 140 | 120 | ||

| 2 | 400 | 200 | 170 | 132.0 | |

| 2.5 | 330 | 140 | 170 | ||

| 3 | 275 | 110 | 125 | ||

| 3.5 | 200 | 150 | 130 | ||

| Session 2: | Mixed use of seasoned Maple, seasoned Poplar, limited use of wet Ash | ||||

| Blower set at about 80% speed, then 100% speed | |||||

| Fire fed exactly every 8 minutes with the fire encompassing the firebox - particular attention was paid to using the full depth | |||||

| Time (h) | Litres | L/hr rate taken every 30 mins | L/hr rate taken hourly | Session Average L/hr rate | |

| Blower set to 80%, seasoned Poplar being burned | |||||

| 0 | 860 | ||||

| 0.5 | 700 | 320 | |||

| 1 | 585 | 230 | 275 | ||

| Blower Set to 100%, seasoned Poplar being burned | |||||

| 1.5 | 430 | 310 | 270 | ||

| 2 | 290 | 280 | 295 | 264.3 | |

| 2.5 | 175 | 230 | 255 | ||

| Blower Set to 100%, seasoned Maple being burned about half way into this 30 min interval | |||||

| 3 | 50 | 250 | 240 | ||

| Switch to Tank 2 | |||||

| 3 | 710 | ||||

| 3.5 | 560 | 300 | |||

| 4 | 425 | 270 | 285 | ||

| Blower Set to 100%, seasoned Poplar being burned | |||||

| 4.5 | 325 | 200 | 235 | ||

| Blower Set to 100%, 50% seasoned Poplar 50% wet Ash being burned | |||||

| 5 | 200 | 250 | 225 | ||

| 5.5 | 60 | 280 | 265 | ||

| No further wood added | |||||

| 5.75 | 0 | ||||

| Boiling Session Comparison | Litres/hr boil rate | Percentage difference | |||

| Session1 | 132.0 | -100.26 | |||

| Session2 | 264.3 | ||||

| Wood Type Comparison - Session2 | Litres/hr boil rate | Percentage difference | |||

| Average Boil Rate using only Seasoned Poplar: | 274.0 | ||||

| Average Boil Rate using only Seasoned Maple: | 273.3 | -0.24 | |||

| Average Boil Rate using 50% Seasoned Poplar, 50% wet Ash: | 265.0 | -3.40 | |||

| Blower Speed Comparison (same wood being) - Session2 | Litres/hr boil rate | Percentage difference | |||

| Average Boil Rate at 80% blower speed: | 275.0 | ||||

| Average Boil Rate at 100% blower speed: | 273.3 | -0.61 | |||

| Conclusions: | |||||

| - TWICE (100.26%) the efficiency was achieved in Session2, largely by having a larger fire and feeding it on a more frequent and more regimented schedule. | |||||

| - Size of fire makes a big difference. This was the one of the two largest factors differentiating Session1 from Session2. Use the full length and breadth of the firebox. | |||||

| - Frequency and Consistency of feeding the fire makes a big difference. This is the second large differentiator between Session1 and Session2. A consistently hot fire is needed. | |||||

| - Using Seasoned wood helps, but as long as the fire is hot and fed frequently, some wet wood won't hurt too much (only a 3.4 reduction in boil rate was seen). | |||||

| - Species of wood doesn't make any appreciable difference as long as the fire is fed frequently enough. Poplar is consumed much more rapidly than Maple so more pieces of Poplar needed to be added (probably in the 2x ballpark) than Maple during the same 8-minute feeding intervals. | |||||

| - Blower speed, as long as high enough to produce a good draft, doesn't seem to make a big difference (less than 1% change between high and full speed). | |||||

| Further Investigation: | |||||

| - I'd like to do some data collection with only blower speed being the variable, ranging from Off through Maximum speed with increments of, say, 20% to see which setting is the most efficient. | |||||

| - It seemed to me that the amount of wood consumed per unit time in Session2 was very similar to that of Session1 even though water was boiled off at twice the rate. I'd like to actually collect data to see how boil rate affects wood consumption | |||||

| - We still need to add 8' to our smoke chimney. I couldn't do it this winter due to four feet of snow on the roof making it impossible to install the needed guy wires. I suspect adding the chimney height will affect what blower setting should be used. I'd like to collect data to determine that. | |||||

| Notes: | - The steeper slope of the red line indicates faster boil rate | |||||

| - The straighter red line indicates a consistently fed fire | ||||||